LECTOR SERIES IMAGE-BASED CODE READERS

Image-based code readers are indispensable in many industries. In an industrial environment, SICK’s Lector® series readers ensures high speed, efficient processes, and reliable code detection.

Reliable 1D and 2D image-based code readers for product traceability and anti-counterfeiting solutions

- Flexible reading of various code types regardless of the code alignment. For example, 2D codes such as data matrix codes.

- Monitoring of code qualities to optimize processes by using code analytics in the device

- Subsequent image analysis as images of identified objects are stored

- Reading, evaluation, and analysis of severely damaged codes due to corrective image processing algorithms.

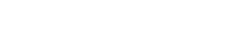

Consumer Goods / Packaging Industry

The Lector series enables fast and error-free code capture and ensures high cycle rates in packaging, food and beverage, and pharmaceutical industries.

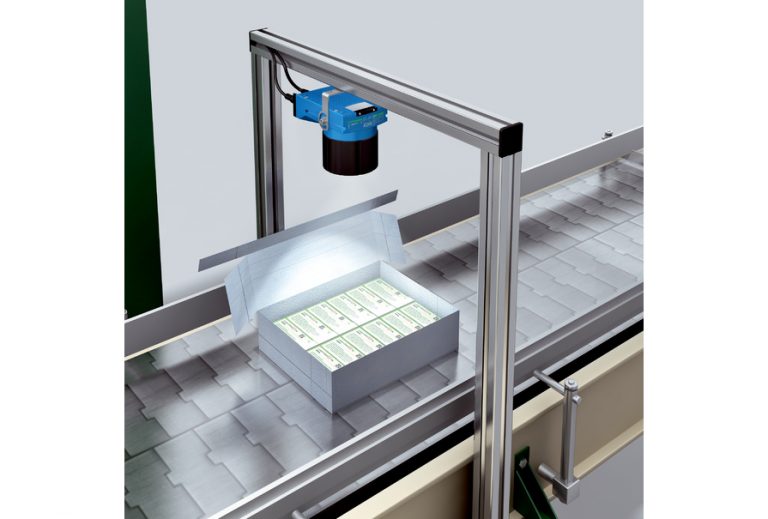

Automotive Industry

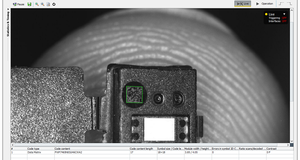

Whether data matrix codes on printed electronic components or directly-marked 2D codes on solar wafers – even the smallest codes for part tracking and quality assurance are detected.

Electronics Industry

Powerful algorithms solve demanding applications when reading needle embossed DPM codes.

SICK OFFERS A RANGE OF ID READERS FROM THE LECTOR 61X FOR MINIATURE CODES TO THE ADVANCED 65X. WE CAN HELP YOU SELECT THE RIGHT ONE FOR YOUR APPLICATION. CONTACT US TO CONSULT WITH ONE OF OUR ENGINEERS OR SCHEDULE A DEMO.

LECTOR 61X MADE FOR ANY TASK

A small image-based code reader for miniature codes and much more

Like small codes | Micro-codes smaller than 1mm

Mounting within 10 seconds - Watch the video!

The Lector61x is the smallest image-based code reader of the Lector® series. It is used for the reliable detection of 1D, 2D and stacked codes and is characterized by excellent reading properties for very small codes, regardless of the surface quality or the material color. Ideal for production lines where space is tight.

Fields of Application:

- Consumer goods industry, serialization and package content monitoring

- Electronics & Solar Industries: PCB, component and device ID

- Automotive Industry: Production Control and traceability of devices

- Conveyor and Storage Systems: Tote Identification

Highlights:

- Compact space-saving design

- Snap-in mounting done in seconds

- Stepless focus adjustment from 50 to 300 mm with millimeter precision

- Controllable multi-color lights with optional polarizing filter

- Magnifier effect for detection of the smallest codes

- Easy auto set-up

- Integrated laser distance measurement (ToF)

- Powerful DPM code reader

Space-saving format with flexible mounting

Thanks to the connector with flexible cable routing and its ultracompact size the Lector61x can fit into very restricted installation spaces on assembly machines.

Integrated magnifying effect

It offers a read range of 50 to 300 as well as an optical design with magnifying effect which enables it to read micro-codes of less than 1 mm in size.

Likes low contrast and all colors

Can read low-contract and distorted DPM codes. Plus it masters a variety of surface colors and characteristics.

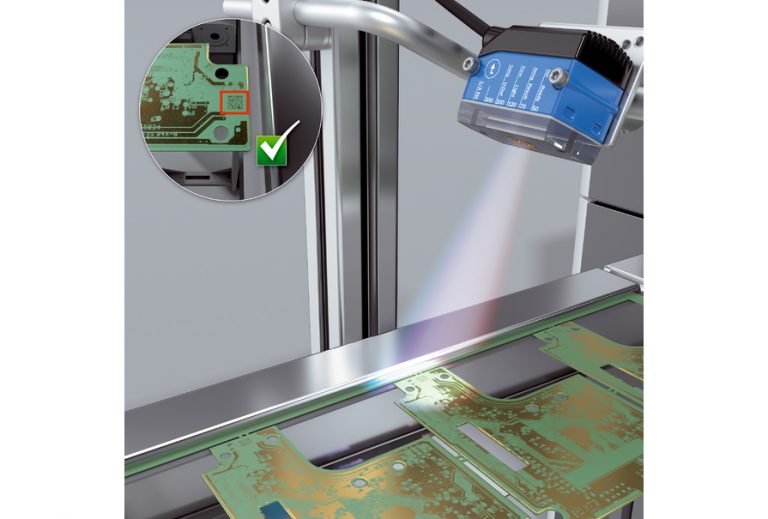

LECTOR 65X FOR NONSTOP CODE READING FLEXIBILITY

Maximum flexibility with moving belts

The Lector65x image-based code reader stands up to the challenges of factory automation and logistics. It reliably identifies 1D, 2D, and directly marked codes at the highest possible speed. An image resolution of 2/4 megapixels gives it a large field of view. In combination with its dynamic focus, the highest levels of flexibility are achieved for code positioning, object height, and transport speed.

Fields of Applications:

- Aggregation of food and pharmaceutical packaging

- Identification of codes and tracking serial numbers & manufacturing dates in pharmaceutical distribution applications

- Material handling in automated sorting systems

- Presentation camera for manual package sorting

Highlights:

- 2/4 megapixel resolution; high frame repetition rate of 40 Hz

- Dynamic focus adjustment from object to object

- Integrated high-power LED illumination

- Function buttons, aiming laser, optical and acoustic feedback signal

- Intelligent, rapid decoding algorithms

EXAMPLE APPLICATIONS

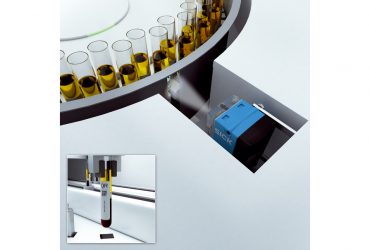

Identification of 1D and 2D codes in pharmaceutical

1D and 2D codes must be identified in the sample carousel which is difficult due to the limited space. However, the Lector61x image-based code reader with its small design and flexible cable routing enables reliable code identification, even in very tight spaces. The integrated special optics with magnification effect can read the smallest codes with up to 0.02 mm (1D) and 0.04 mm cell size (2D).

Identification of product content, supplementary sheet, label and packaging through linear or 2D codes

When a product is packed, it is important to ensure that the packaging, supplementary sheet, and label are used in the correct combination. The Lector62x can reliably read and match up medical packaging. Intelligent identification algorithms ensure that different 1D, 2D, and stacked codes, and plain text can be read on all sorts of materials.

Multifunctional code reading

For smooth tracking of drugs, serialization must be ensured in all production steps. When bundling folding boxes, the serial numbers of each box, which are contained in a data matrix code, must be determined and checked for completeness. The Lector65x image-based code reader can determine the content of all codes with just a single image.